now for some fun

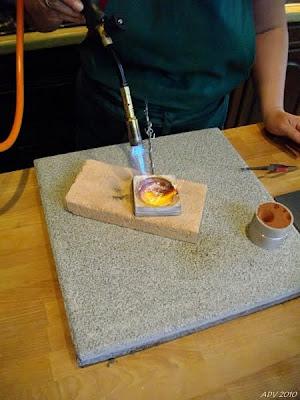

remember i wrote about going to the wholesaler last week and that i d bought a casting set? it contains an aluminium mold, very heavy clayish sand, and a dvd with instructions... gosh, it all looked so easy, and since ofcourse it had to start raining again, Sam and i said we might as well try it out... i also wanted to test if my gasburner was gonna give off enough heat to melt some silver for casting

here are some pics:

preparing the mold

melting fine silver and copper

slowly getting there

will it, will it not?

NAAAAAH, just got these little blobs!

and the reason it didn t go well, is because i just couldn t get the heat high enough for the silver to remain fluid enough to pour...

must admit though, it was fun and pretty exciting to be able to do this at home. can t wait for the next few free days when i can try again. Sam did say he had a burner in his atelier that s a little more powerful, so we will try it out.

i must find a way to get this right, because, as ever, practice makes purrrrfect...

wow, interesting! this is so foreign to me, so how are the silver and copper supposed to come out like? if I used this, I'll probably burn everything around me....

ReplyDeletesilver 925 is what most silver jewelry is made of. this means that 925/1000 (so for 10 grams = 9.25 grams) is fine/pure silver and copper 75/1000 (so 0.75 grams) is added to make the silver alloy... you need the copper to make the silver hard enough to make jewelry out of, otherwise it would be too soft and bend...

ReplyDeleteit was quite funny, and also a little frustrating, haha... but we didn t burn anything, thank god ;-)